What can Powell Valley offer over competitors?

PVM processes three thicknesses of lumber: 4/4, 5/4, and 6/4. The addition of 6/4 gives a competitive advantage with resawn variants and gives the sales team another option to present to the customer base. Below are two scenarios which demonstrate the 6/4 advantage.

A bevel resaw allows maximum utilization of the board usage by resawing at an angle. This works well for casing style profiles

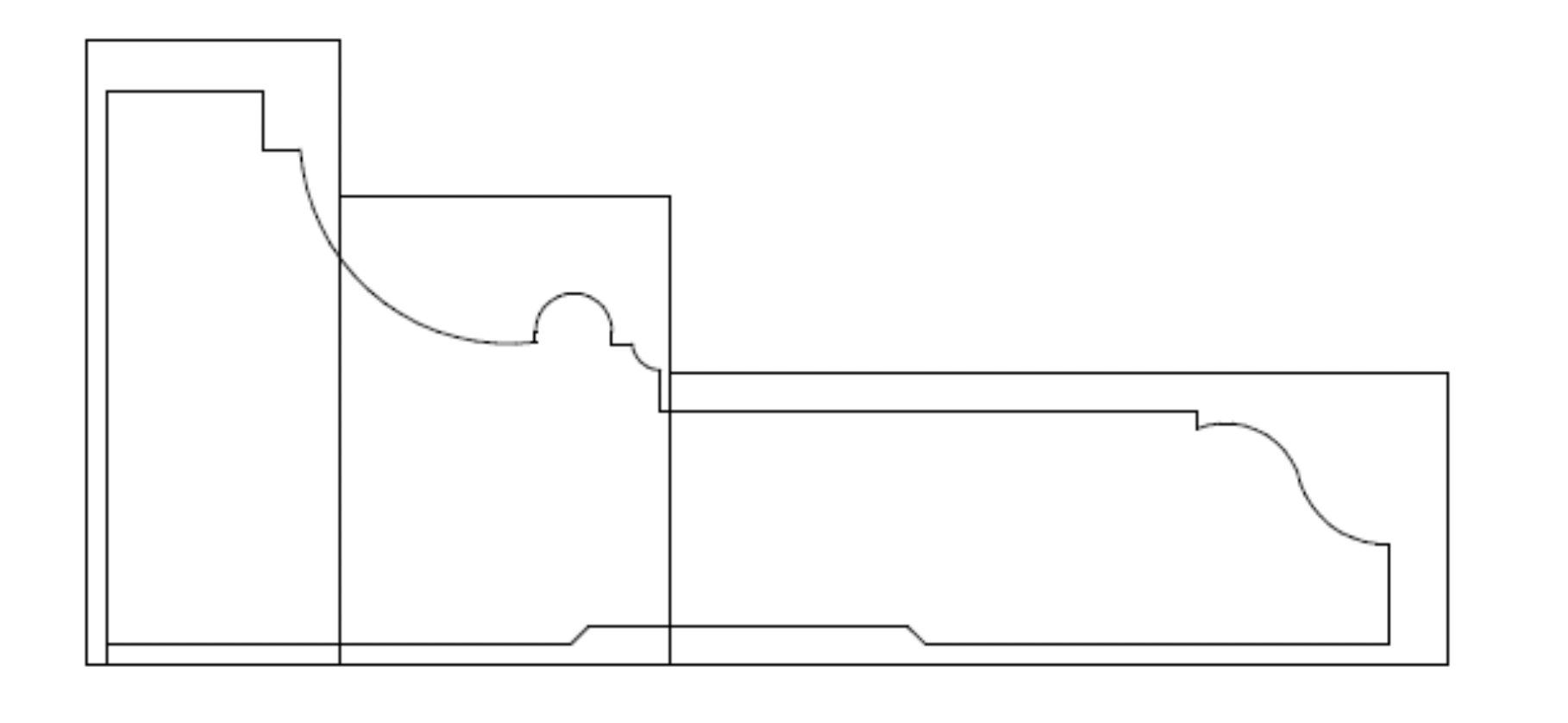

6/4 allows recovery of 2 full 9/16” profiles from a flat resaw. An excellent option for baseboards or S4S for a budget conscious customer. See below comparison to a standard 11/16” baseboard.

PVM produces a large volume of face-glued and edge-glued products allowing for virtually unlimited options for profile shapes and sizes.

Constructing a blank to the shape of the profile maximizes lumber yield and lowers cost over a traditional square one-piece blank. Note on the example below how the blank follows the shape of the casing to minimize waste

We are a domestic mill eager to develop new programs and are amenable to questions, changes, and requests from end user.

Capability to match any existing program or customize to needs of customer – competitors typically will not

Provide Inkjet for custom branding or jobsite logistics (floor #, tower #, etc.)

Day-to-day owner and management engagement. Ability to jump through hoops for lead time or special project work

Advantages to Poplar over Pine & MDF

Poplar is a significant upgrade in species compared to Pine or MDF. Consider the characteristics of a hardwood when communicating with customers.

Stronger, harder, more dense substrate

Durable option for residential and commercial applications. Resistant to normal wear (vacuums, children, furniture)

Will not expand and contract from humidity fluctuation as significantly as Pine and MDF

Takes paint and stain better than Pine and MDF

Domestic mill has ability to beat lead times from offshore. Standard 4-5 week lead time

Consider the carbon footprint of a domestically sourced product rather than buying from a source that does not adhere to same environmental and conservation standards as stateside. Also, consider the pollution of vessels carrying material overseas.